The supply network pipes are generally buried in the basement of populations, under sidewalks, asphalt, cobblestones, etc., filled with embankments, sandstone, ballast or cased and protected in concrete with road crossings or points where they can sustain high loads. Pipes visible on the surface or within open galleries are not common. Just in case, finding the exact repair points and repairing them would be easier.

Clean break, round or break : the cutting of pipes on a more or less perpendicular plane

Pitting : small hole generally produced by the external action of machines on site or by the action of corrosion. Sometimes we find damage caused by leaks in old branch socket flanges, which when removed expose the hole made in the pipe. We can consider this hole, as far as its repair system is concerned, similar to a puncture.

Cracking : small longitudinal opening on the surface of the pipes. External action of machinery or excessive pressure can cause pipes to crack.

Bursting : the external action of machinery or pressure can cause pipes to burst.

Damage by clean, round or broken rupture : for its repair, a flexible coupling or a repair collar is used, having a width sufficient to cover the entire damaged area with at least 5 cm on each side. However, eliminate the damaged part by cutting 1 cm on each side and put EF sleeves or flanges for PE pipes and threaded sleeves for PVC pipes.

Puncture damage : in the case of a prick, the repair is made with a repair collar of sufficient width to cover the entire damaged area with at least 5 cm on each side.

Damage by cracking : when the cracking is less than or equal to 1/3 of the external diameter of the pipes without the possibility of progression, a repair collar is used with sufficient width to cover all the cracking at least 5 cm on each side

Burst damage : in the event of a pipe burst, the damaged part must be cut off. Similarly, it is recommended to replace the hose.

Coils

First, for the repair of coils, the damaged part must be removed. In case of PE pipes, we can use plastic or brass sleeves, electrofusion sleeves or flanges . In my opinion, electrofusion sleeves are a solution to take into account, especially those with diameters greater than 63 mm.

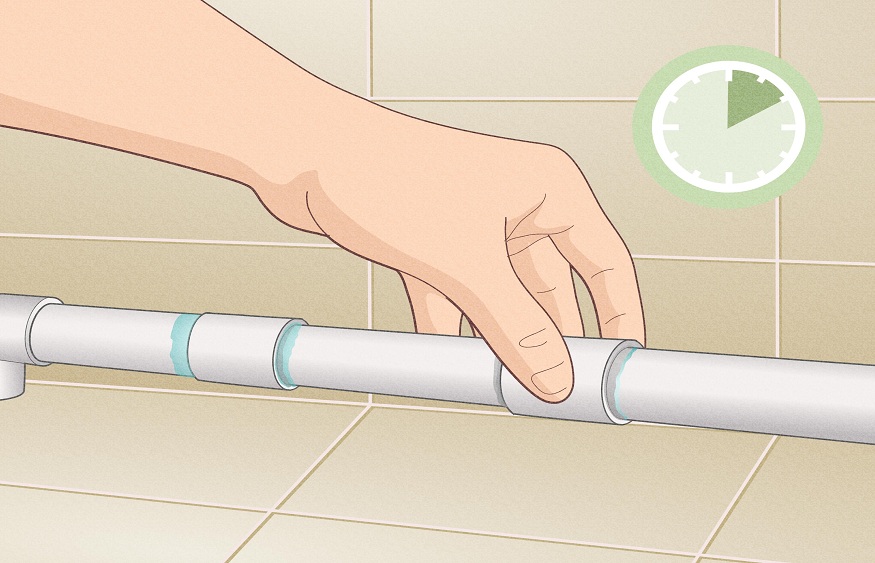

Electrofusion collars or supports are very useful for repairing pitting damage, by scraping the surface of the welding beforehand.

In case of pressure PVC pipes , we can use female-female couplings or flanges.

Similar to the reel with pressurized pipe sleeve is the method of repairing pipes for pressure free sanitation with sleeves as we indicate below: